Bikotronic-Industrie-Elektronik GmbH Im Hohen Acker 7 67146 Deidesheim Germany Tel.+49632696530 Fax.+496326965350

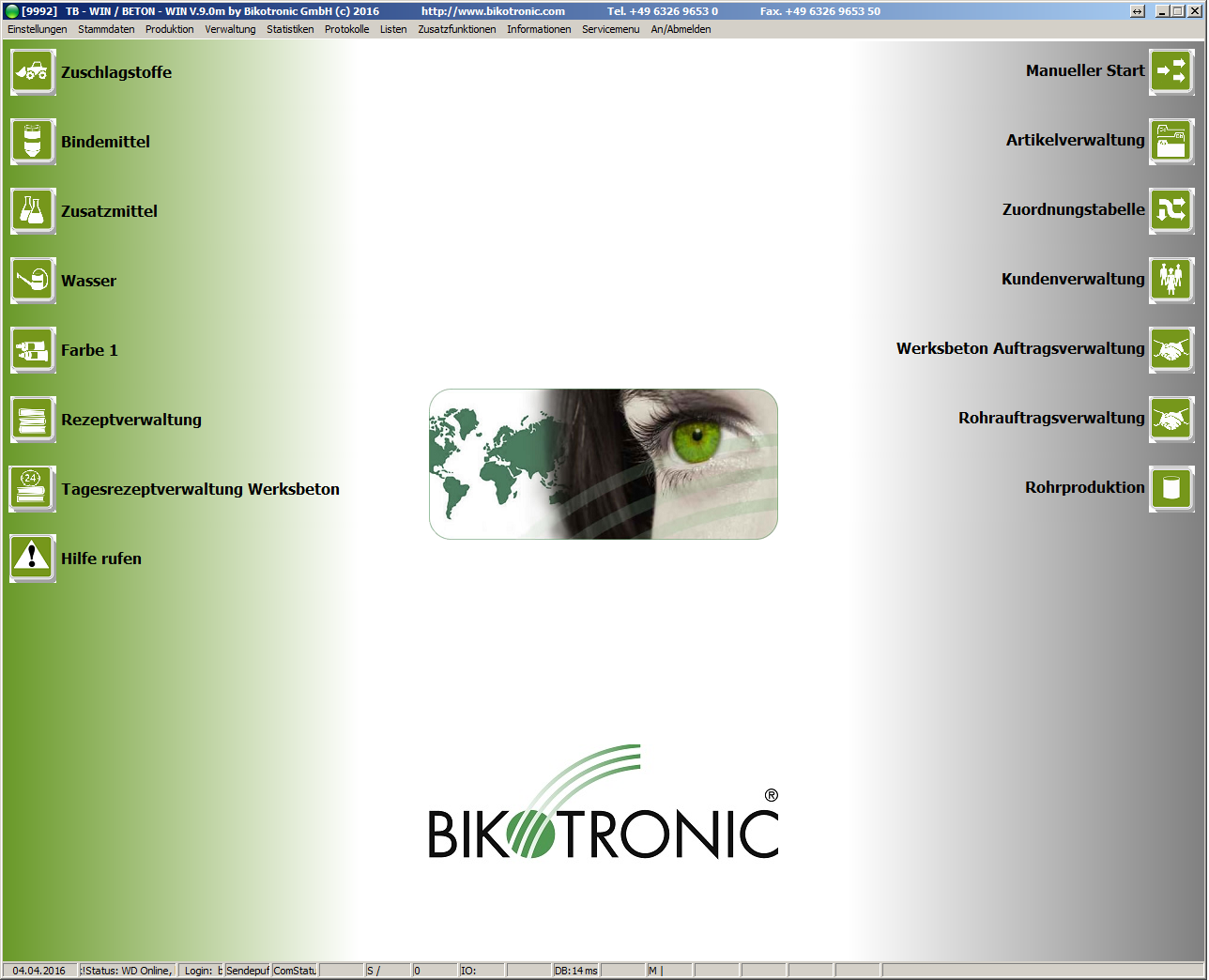

Recipe administration

- Entry of qualifications, concrete families, exposure classes, product groups, components, emptying times, scales, mixer closing times related to smaller batches, other times

Materials

- Aggregate, cement, additve, water, 50 preset each, inventory management for each silo, data export of the inventory as text or Excel file (*.csv)

Master data administration

- Administration of customer addresses with name, place, search term, street, phone, remarks and lock indicator, accessible through customer number or search term

- Administration of construction site data with allocation to the customer

- Administration of vehicle data including load quantity, licence number, name of the driver and low quantity

Order processing

- Processing of main orders and pre-scheduled orders

- Selection for print-out with actual values or advertising texts

- Pre-print of delivery notes

- Deletion of orders after completion, separately, selected or after an adjustable time in days (max. 9 999 days)

- Cash sales module: invoice print-out on the delivery note

Material scheduling

- Scheduling for all components

- Scheduling with selection of single orders

- Automatic calculation of quantities

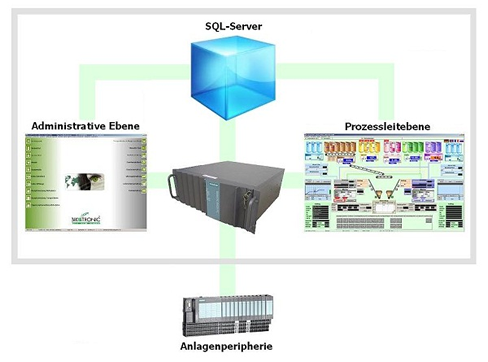

The Beton-WIN process control system consists of:

- 1 industrial PC

- 1 or more LCD displays 22, 24 or 26 inches

- 1 keyboard

- 1 mouse

- 1 remote maintenance module

- 1 USB stick for data back-up

- 1 Recovery DVD

- 1 Beton-WIN administration and process control software

- 1 Windows 7 licence

- 1 SQL data base licence

- 1 Soft PLC licence

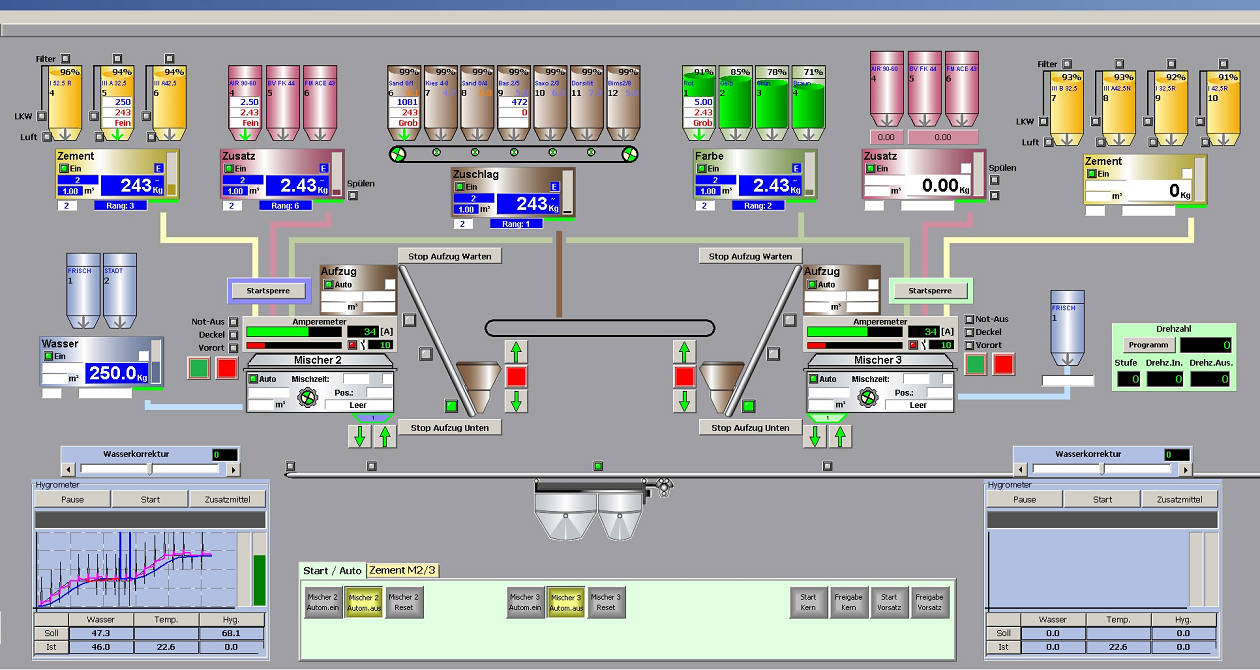

Production

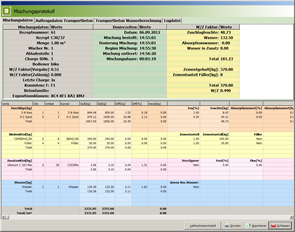

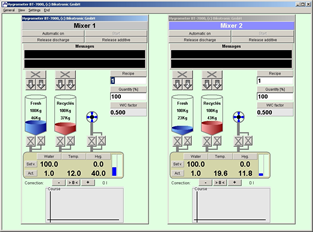

The process control software control the batching process in manual and automatic operation. The mixing plant is displayed schematically. All relevant processes and plant statuses as well as error messages in clear text with time and date are graphically displayed.

- Recipe controlled production process

- All scales are displayed on the screen

- Operating System Windows 7

- Adjustment of the water correction and the mixing rate fresh / recycling water with the mouse

- Display of the process diagram

- Continuous automatic overrun calculation for each recipe

- Water stop function by mouse click on filling and emptying

- Change of quantity during production

- Change of silo while dosing

- Double filling lock for mixer

- Control times of the plant individually adjustable

- Output of error messages

- Operating hours counter for all drives

- Maintenance module: Every motor, valve and every limit switch can be monitored. If a beforehand defined condition is fulfilled, a message in clear text will appear and it will be saved in a file for later processing

- Calculation of the solids density

- Graphical display of the dosing accuracy for each component

- Filling level calculated and measured by sensor

- Allocation table for articles

- Colormix

- Start with recipe number, article or discharge position

- Precast order administration with consumption statistics

Article administration

- Selection of several recipe number for one article

- Start parameter for the production and bucket conveyor

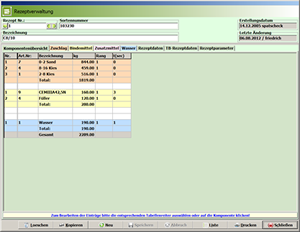

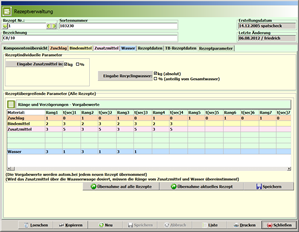

Recipe administration

- Entry of recipes with recipe number, recipe name, components, set values, hygrometer control etc.

- Calculation of the composition of the fresh concrete volume

- Daily recipe management

Forms administration

- Entry of the forms, also of external plants

- Number of cycles statistics for each form

- Administration for form repairs

- Form statistics with article management

- Connection to the paver machine

Statistics

- All statistics can be output with any time frame

- Material consumption statistics with administration of material dispatch, set/actual comparison with difference calculation, according to recipe, article, customer, delivery note, user etc.

- Recipe statistics

- Article statistics: Listing according to produced articles with consumption of aggregates, cement, additives, colour and water for every article

- Production statistics with all components included in the recipe with itemization of theoretical and actual values including difference calculation

- Mixing protocols: selection of every single dosed batch with order data, dosing times, manual intervention

- Statistics of the mixing protocols for every single batch

- LOG File – All processes of the system are recorded and stored in a LOG file

Additional features

- Protocol printout with any time frame

- All protocols and statistics can be exported.

- Recording of all operating functions and system errors for later analysis of the equipment

- Change languages by pushing one button (if delivered with a foreign language)

- Data transmission

- Interfaces to the invoicing, disposition, ERP, lab

- Drilldown function

Data export

- Data export in ASCII or Excel Format for later data processing xls, xml, csv, txt

Data import

- Import of recipes, orders, articles, customers, construction sites, vehicles

Data base

- SQL Server

- Server client application

- Automatic backup system

- Independent repair system

Functions protected by password

- Every menu item can be protected by a password: no access, only read access, read and write access.

Recovery Set

To restore all Bikotronic software packages and databases easily. The recovery can be managed by the customer without any problems. The Recovery Set consists of:

- Bikotronic Ultimate-Boot-CD and Recovery DVD for restoring all Bikotronic software package and data bases

- Acronis TrueImage software package and manual

- USB stick as memory

Remote maintenance Beton-WIN

Through this connection all functions of the plant can be tested, accepted or changed.

- through ISDN, network or internet (VPN)

- Remote maintenance software TeamViewer

- Remote maintenance for I/O interface (PLC)

- Remote maintenance for BTK-WIN

- Remote maintenance for BTS-WIN

- Remote maintenance for BTW-500 scale display

Spare parts provision

The hardware of the Beton-WIN SQL system is based on standard industry computer hardware. Thus, a fast and easy spare parts provision is ensured by standardized PC components.

Options

Water Batching System BT-7000

Nowadays, the concrete quality is of vital importance for the industrial production process. In order to meet the increasing quality demands, it is essential to control and regulate the moisture content. The Water Batching Computer BT-7000 determines the moisture of the concrete in the mixer

fast and exactly. It calculates and doses the water to be added and is thus the basis for a constantly optimal concrete quality.

Sand Moisture Measurement BTS-WIN

The BTS-WIN measures the moisture continously while the batching is running. Afterwards the sand / water correction will be executed during the batching.The measured sand moisture values are displayed in the corresponding silo.